- RFID Asset Tracking System

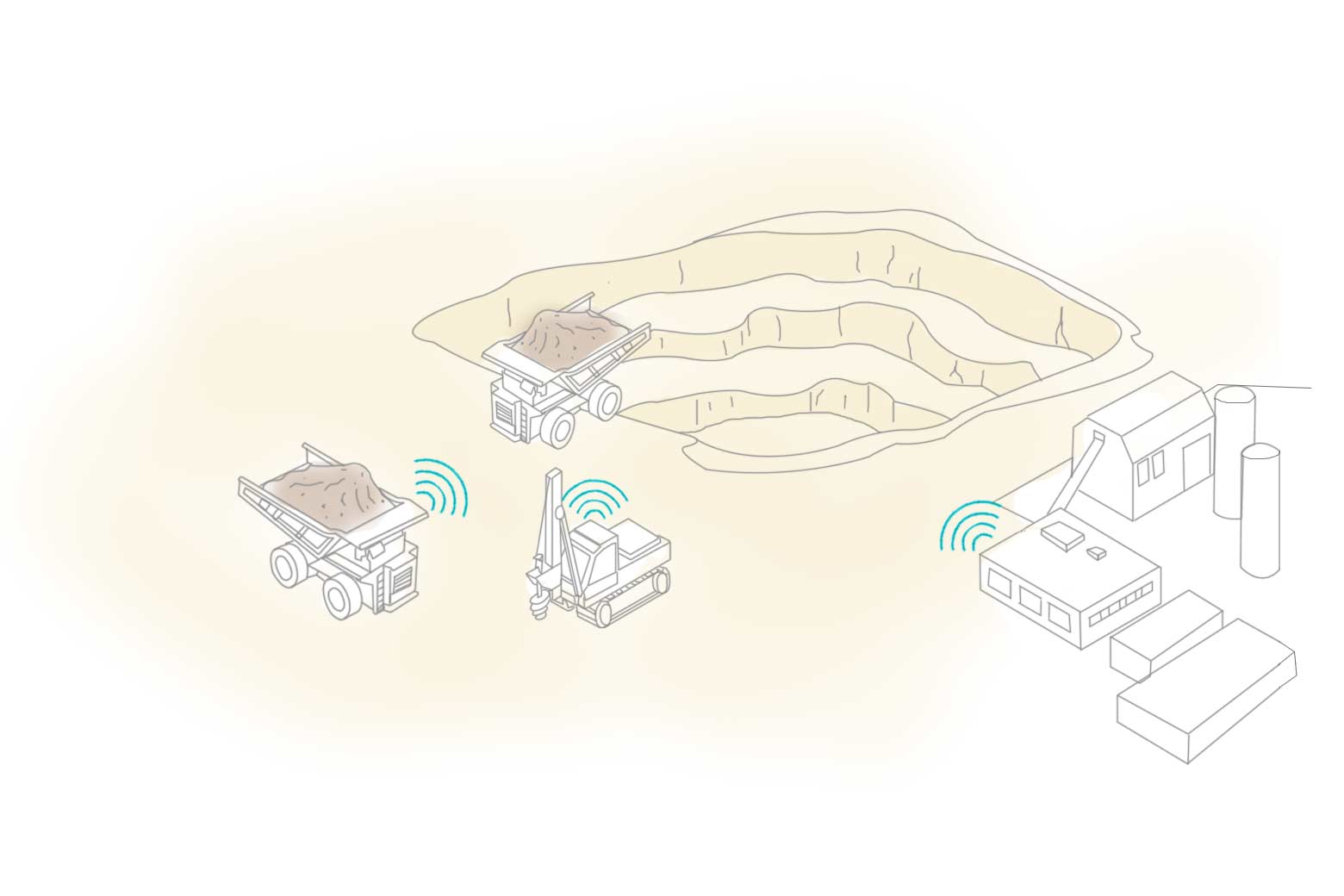

- Smart Mining System

- Employee & Visitor Tracking System

- Traceability Applications

- Manufacturing RFID Systems

- Warehouse RFID Systems

- RTLS with RFID

- Retail & Apparel RFID Systems

- Document Tracking RFID Systems

- Healthcare RFID Systems

- Event Management RFID Systems

- Automatic Vehicle Identification

- Parking Management with RFID

- Returnable Transport Items Tracking

- Waste Management with RFID

- Personnel Safety RFID Systems

System Features

- Equipment and personnel visibility

- Improved throughput and operations

- Compliance management

The mining industry demands managers to be under a lot of pressure in order to be more efficient. It also requires smart systems for building a safety and cost management culture.

With the help of IoT, develop an entirely new competitive edge through monitoring tunnel and mineworkers, tracking equipment and tools, optimizing the fleet resources in underground and open mines.

Our systems measure data from a wide variety of sources in order to improve safety in mining industry. We precisely track and record location of each mine worker. We help you monitor environment and take action to boost underground mining safety. Our systems track each vehicle under or above the ground in order to help control vehicle traffic, hence preventing collisions.

Our integrated systems measure data from several sources for improving safety in the mining industry. The location of mineworkers are tracked and recorded with the help of our system. Our solutions help you take action and monitor environment that efficiently boosts underground mining safety. The systems essentially track each vehicle above or under the ground that helps to manage the vehicle traffic, thus preventing collisions. Entrust our next generation RTLS and mining IoT system for giving a boost to safety and efficiency in the mining industry.

A. Safety at work place

- Monitor and automate gate access

- Report any personnel working above, under ground, or anywhere in tunnel, gallery and zone

- Instantly locate and identify missing individuals

- Prevent and avoid collisions between people, vehicle or any other asset

- Maintain and trace tools of firefighting, first aid kits and various other emergency equipment

- Regulate an optimum line of safety that comprises of built in panic buttons inside personnel tag

- Get notified during any prolonged personnel activity

- Enforce skill levels of workers for eliminating unauthorized access of specific areas and vehicles

Production Tracking

- Avail real-time transparency of material flow right from the pit to the port that includes trips, cycle times along with filled buckets

- Monitor the operating rate and time, KPI’s along with key statistics

- Improve the maintenance of equipment while reducing downtime during repair

- Offer a clear decision-making tool beneficial for supporting sustainable operational improvement

- Quickly grasp and solve problems regarding production

- Automate weighing, scales, unloading and loading stations

Total Asset Visibility

- Instantly locate any container, mobile asset or any equipment

- Make ‘geofences’ that set predefined boundaries on the assets transport

- Create “geofences” that put predefined boundaries on assets transport

- Monitor maintenance status of the assets in order t streamline the repair processes

Tracking vehicle and signalization

- Continuously monitor location, status and usage of vehicles – above or under the ground

- Control signalization, traffic infrastructure’s entirety and access

- Create gates, boundaries and virtual zones which essentially controls the inbound and outbound traffic

- All assets in the vehicular inventory needs to be accounted for

E. Gas and Environment Monitoring

- Monitor the humidity and environment temperature in order to ensure valuable production and optimal working conditions

- Automatically activate all auxiliary devices that includes ventilators and fans

- Monitor gas levels (CO, H2S, NO, O2, CO2) and receive automated alerts

- Compliance management

- Monitor the gas level (CO, H2S, NO, O2, CO2) and get automated alerts

- Automate audits and checklists comprising of real-time monitoring system

- Conduct constant validation of consistency of resources in order to ensure regulatory compliance

- Automate audits and checklists with real-time monitoring system

- Monitor and maintain inventory of the compliance-mandated equipment